Emergency: TSMC 12-inch fab has outbreaks of industrial pollution accident in succession together with foundry orders loss(2)

Client orders decline extends to 16nm and 7nm from 28nm

Actually, global economic has begun to ease from high price since the second half of 2018. As 28nm orders cooling down, 12/16nm process still has a great demand with a flood of orders. This situation lasts to early 2019, while 12/16nm process orders are said to be no longer in damand recently. Whole orders apparently cool down.

12/16nm capacity use rate of TSMC Nanke fab 14 declines to 80% but Nanke fab 14 has already been backbone of TSMC, compared with 28nm capacity whose capacity use rate is only 60% or even lower.

It is said that 28nm capacity is at leisure too long that every quarter capacity use rete continually sets new low, so TSMC internal considers to power off 28nm machine first.

“Pollution” accident is different from “virus” event but it isn’t a small accident which affects ten thousnad wafers

TSMC has an outbreak of “virus” event causing a sensation in semiconductor on August, 2018. Its revenue loss is about $2.5 hundred million, but recognizing of final fanancial report shows revenue loss is less than $1 hundred million.

The outside world wonders why TSMC, who are watertight in information security, meets such a outrageous virus attack, which occurs in more than one factory. Due to virus attack across factories, related effect results in each semeconductor factory beginning strengthen their information security lest core secret leaks out.

“Pollution case” on 28 is different from virus attack before. According to inductrial analysis, operation of a fab is sophisticated, because kinds of semiconductor chemicals and raw materials for semiconductor lead to unepected conditions are of common occurrence, which isn’t a small accident involving clients processing or compensation later.

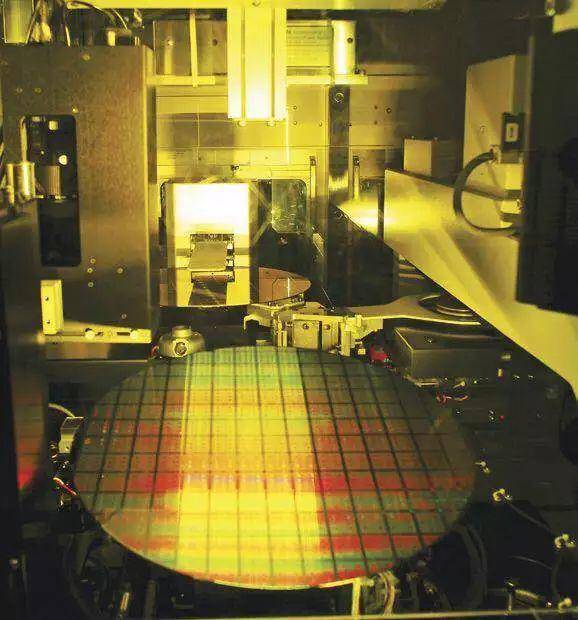

Figure Operating of a fab is sophisticated, because management of various semiconductor chemicals is difficult that unepected conditions are of common occurrence

Manufacturers jokingly says the pollution case save TSMC’s clients now that there is a downturn of market, so many wafers are needless. Thus, they can reduce their orders. However, follow-up compensation can be troublesome if the accident occurs in full capacity.

It is obviously jokingly saying in industry, because when IC design client tips out their orders, there will be strict quantity evaluations according to different technologies. It just reflects semiconductor industry struggling recently while orders and demand are falling.

Recently, client reducing orders not only in 28nm, but also in 16nm and 7nm, which is always in great expectation. TSMC also confirms it no longer in full load condition with an eased capacity use rate.

It is well aware in industry that main reason is Apple reducing its orders. As Apple accounts for two thirds of TSMC 7nm process, once Apple reduces its orders there will be a shortfall in orders with no one can recover inmmediately, even if there are many clients, AMD for example, for TSMC 7nm.

Therefore, according to 2019 profit outlooks released by TSMC, revenue declines by 22% compared with last quarter, revised downwards is larger than market expectation and gross margin delines between 43% and 45%.

Moreover, global economy growth slows down. Expected growth rate of 2019 global semeconductor industry falls to 1% from 8% in last year(without memory), wafer foundry growth rate is flat which is lower than 6% in 2018.

TSMC Nanjing fab 12 also imports 16nm first and further 12nm technology will be imported in the future.

The first client of Nanjing fab is the legendary Bitmain in 2018. Bitmain is said to show up that they plans to own whole 15-20 thousand capacity of Nanjing fab when Bitcoin has a high price. However, it is impossible after Bitcoin collapse in 2018.

Downturn of semiconductor industry is well known. As leader of global wafer foundry and top three semiconductor(without memory), TSMC releases its revenue warnings each quarter, which affects operating nerves of whole IC industry.

However, after “virus case” on August, 2018 happens, industrialaccident frequently occur in TSMC. “Double accidents in a day” worries people on management in factory of TSMC. The wrong chemical specifications can ascribe to suppliers, but strengthening internal security maintenance and supply chain management in each level after is a more essential problem.