SK Hynix starts the mass production of the first 4D NAND flash memory:the stacking of 96 layers, with a speed improved 30% than before.

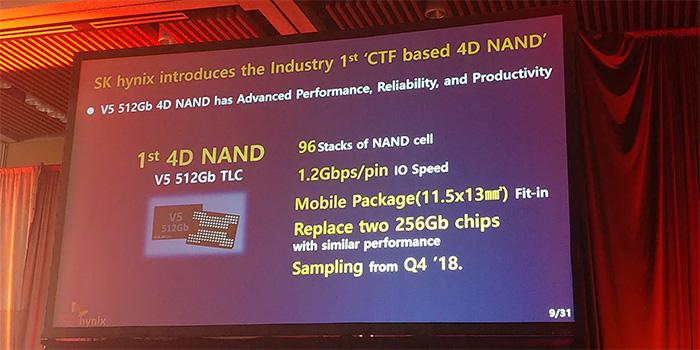

With the mass production of 64-layer stack 3D NAND, the world's top 6 NAND flash memory manufacturers are all turning to the new generation of 3D NAND with 96-layer stacks this year, and the technological solutions of several manufacturers are different. SK Hynix named their new flash memory 4D NAND, and officially introduced the first CTF based 4D NAND flash memory in this industry, in this year’s FMS international flash memory meeting. Recently, they declare 4D NAND flash memory officially starts mass production. The products are mainly the TLC type, which is composed of the stacking of 96 layers and a core capacity of 512GB. With this technology, the core area of flash memory can reduce by 30%, and the reading and writing speed can be improved 30% and 25% respectively.

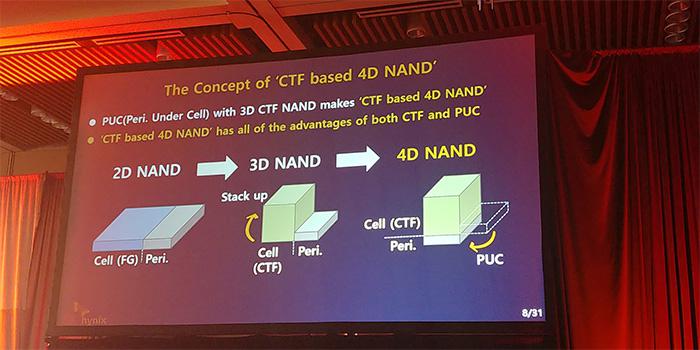

According to messages SK Hynix previously released, the so-called 4D NAND flash memory is actually 3D NAND, which moves the PUC(Peri Under Cell) circuit of NAND flash memory Cell units from its previous position to the bottom. Therefore, it is named as 4D NAND flash memory, but it is still 3D NAND in essence. It is 4D NAND flash memory that has a strong sense of deliberately commercial marketing.

SK Hynix's 4D NAND flash memory will first mass produce TLC type. The two kinds of core capacity are 512Gbt and 1Tb, both of which are 96-layer stacks. The IO interface speed is 1.2Gbps. However, the BGA packaging area of the two is different, the 1Tb version is obviously larger.

As for the type of QLC, it will be the focus of SK Hynix mass production, which has a core capacity of 1Tb. However, the mass production time will be in the second half of next year, and it is still taking time to achieve.

Yonhap news agency reported that SK Hynix officially released the 96-layer stack 4D NAND flash memory on the 4th of this month, which is TLC type and has a core capacity of 512GB. Compared with existing 72-layer stack 3D NAND flash memory, the core area of 4D NAND flash memory is decreased by 30%, the production output of single piece of wafer is improved by 50%, and the performance is stronger—reading speed is improved by 30%, and writing speed by 25%.

According to officials of SK Hynix, 4D NAND would start mass produce this year, and would be mainly produced in the M15 factory, which is just built, with a total investment of 15 trillion won, approximately $13.5 billion.