What is the positive, white and black die particles in SSD? The quality is different.

What is the positive, white and black die particles in SSD? The quality is different.

Nowadays, many people will choose SSD and mobile SSD to be as their data storage tools. The SSD is very convenient, because it has small size, large capacity and fast speed, especially the SSD with M.2 specification. Therefore, most people choose to use SSD, when storing data.

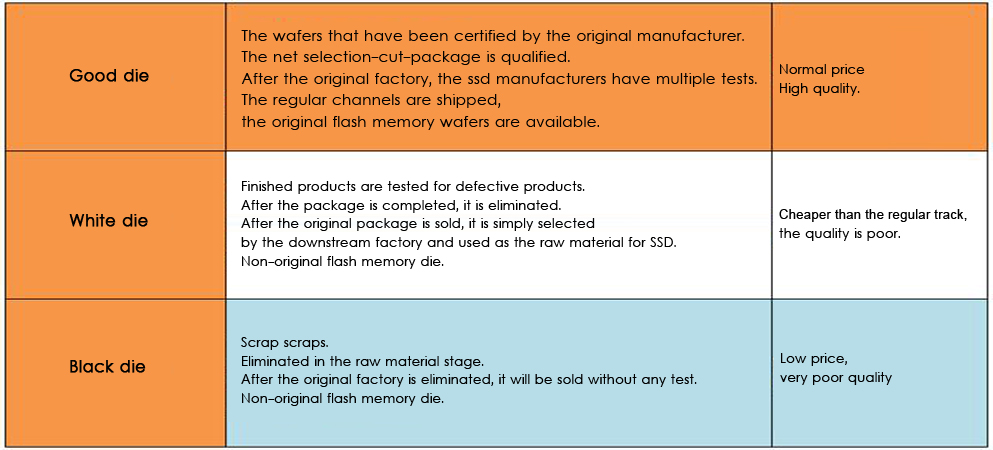

All of us know that the core of SSD is flash particle. While the SSD particles can be divided into positive, white and black die. What is the difference of them.

what is positive die?

Flash particles in SSD are cut from wafers. We cut one by one small square wafers on a circular wafer which is also called Die, then we can test them. The intact, stable and full-sized small-block Die chip has become the positive die of Flash particles after encapsulation and testing.

The circular wafer will be cut into one by one small-block Die chip.

What are white and black die?

While white and black die are made by downgrade particle and downgrade flash. These flash particles that don’t meet the factory requirements are downgrade flash. These particles have some problems, such as insufficient capacity, failure in reading and writing test, problems in temperature and environment text, abnormal current, failure of aging test and so on

The white die is the flawed flash particles detected, after the original packaging. Although the white die is worse than the positive die, it can still be used. For example, Flash 387GB particles with insufficient capacity can be produced to 256GB in capacity which can be used normally and whose quality is acceptable. But the data is easier to lose in long time use, even the capacity of these flash particles which cannot pass environment tests or aging tests.

Black die is the scraps phased out in the raw material link. These scraps will be abandoned in common, but they will enter the market by kinds of ways driven by the benefit. They will be made to some cheap SSD, the quality of these SSD is not good.

How to discriminate white die and black die?

The discrimination method is complex.

Simply speaking, we can discriminate them in price, the price of black die SSD is cheaper. Next, in appearance, manufacturers will use various ways to wash the black die to white, such as polishing the surface of particles, re–carving and so on. So the appearance of black die is tough. It is difficult to discriminate white die in appearance, it can be distinguished after actual experience or testing.

In addition to the excellent quality of the SSD installed in the original packaging test, the products from some powerful manufactures are also good. These manufacturers, such as Kingston and the SSK, will purchase intact wafer from the original factory, and then cut,pack and test by themselves. The flash of its SSD is also the positive die with sufficient capacity from original factory particles.

DRAM-Less SSD are more cost-competitive by introducing HMB.

Those Who Research SSD are Actually Studying These Three Components and Related Professional Compulsory Courses