What's the difference between an etcher and a lithography machine for making chips?

Lithography machines and etching machines are indispensable equipment in the production of modern large-scale integrated circuits such as chips. There is a big difference between them. Let me talk about them in detail.

What is a lithography machine? What is an etcher?

The most popular saying is that the so-called large-scale integrated circuits are to make the circuits we normally see very small and dense, so there is no essential difference between the simplest circuits we normally see and the complex and dense circuits in the chips.

Complex circuit

The simplest circuit

However, in the process of making the circuit very small and dense, we encounter a very serious problem. That is, simple circuit can be built by hand, but how can we build such a small circuit?

With long-term exploration, scientists have found two kinds of substances: metal which we are familiar with, and photoresist. What's so special about these two substances? What does it have to do with chip manufacturing?

In short, photoresist can be eroded by light, but chemicals can't erode it. However, metals can't be eroded by light, but chemicals can erode it. (Although plasma etching is the most advanced method, we will not talk about that here. Let us talk about a more basic principle.)

The basic principle of making chips is to make use of the properties of these two substances. Cover the metal surface with a photoresist, then erode the photoresist with light, and then soak it with chemical substances. Therefore, the part of the metal with photoresist will not be eroded, but that part without photoresist will be eroded. As a result, the metal surface forms the shape we want.

These two processes are called lithography and etching, and the corresponding equipment is lithography and etching machine.

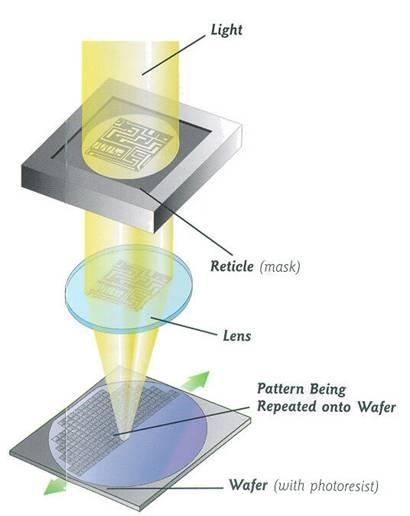

The following picture is the principle of a lithography machine. The shape of the circuit is initially drawn on a larger partition board, and then the pattern of the circuit is reduced to a small size through a lens. Finally, through the pattern of the circuit, light erodes metal plate coated with photoresist (the so-called wafer).

Principle diagram of lithography machine

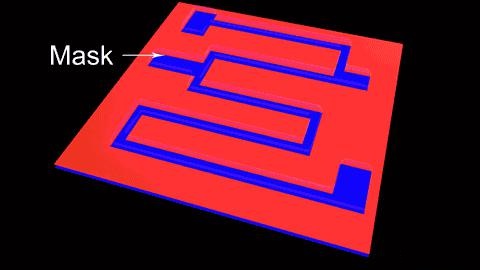

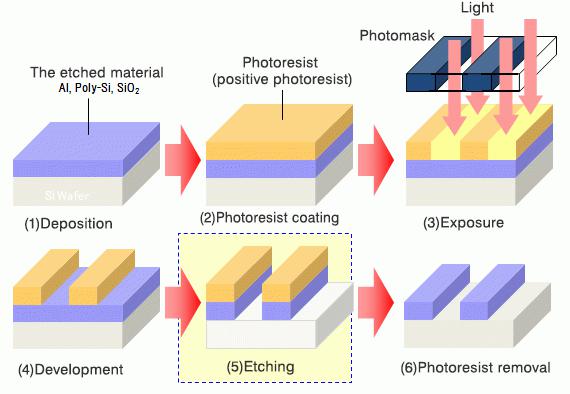

The following picture shows the etching process. It can be seen that the metal without photoresist is dissolved under the action of chemical substances, and then the surface of the wafer becomes the shape we want. The whole process of lithography and etching of large-scale integrated circuits can be seen in the next picture.

Chemical corrosion

Manufacturing process of large-scale integrated circuits

How about the development of two kinds of equipment in China now?

In fact, we can also see from the manufacturing process of large-scale integrated circuits just now that lithography is much more complex than etching, so the complexity of lithography machine is much higher than etching machine. Now the manufacturer that has ability to produce the most advanced lithography machine in the world is ASML in the Netherlands. ASML occupies 80% of the market share. A most advanced lithography machine can sell for $100 million, and it does not accept bargaining.

At present, the light used by ASML has reached the extreme ultraviolet (EUV), so it can lithography large-scale integrated circuits under 7 nm. Affected by the Wassenaar Agreement, ASML is unable to sell advanced lithography machines to China. So China has been blocked for a long time in this respect.

So what is the level of China's own lithography machine? Unfortunately, the level of lithography in China lags far behind the world a lot. At present, the mass-produced lithography machine can only lithography large-scale integrated circuits at 90 nm. The gap with the most advanced equipment is enormous. Perhaps the laboratory has a higher process of lithography technology, but it is only an idea before mass production.

In contrast, China has done a relatively good job in etching machine. Now Chinese most advanced plasma etcher has been manufactured to 5nm process. 7nm process etcher has stepped out of the laboratory last year and started to supply to manufacturers such as TSMC. In this respect, China has become the world's top level.

Chinese etcher above

Therefore, we still have a long way to go on the road of lithography machine, and we should make further efforts on etching machine.

Related Articles:

TSMC purchases lithography machines with $2.2 billion for the second generation 7nm mass production making Apple and Huawei being overjoyed!

Dutch lithography machine gaint ASML: it is optimistic of exports to China due to its strong demand

ASML supplier is caught in a fire and delivery of EUV lithography machines will be delayed early next year.